The Voxel8 3D printer (www.voxel8.co/) can print cavities to place electronics and components and print conductive material to connect them. The video from CES will give you an idea of what they can do. They print a quadcopter frame, pausing to have the controller board, motors, LED inserted in, and print the conductive material to connect them together. Pretty amazing that it is only $9,000.

Category Archives: 3D Printer

Learning SolidWorks

My main goal for today is to be able to learn to do basic things in SolidWorks. This is a popular CAD package that can be used for mechanical design. I have some visions for some robotic devices, and I think the first step is to be able to get them into some tangible form. The Artisan’s Asylum has a computer lab with SolidWorks installed. And I have a class tonight on Analog Electronics that I have to go there for anyway. So my plan is to buy a day pass, spend the day going through tutorials and creating some very basic physical designs.

At the present time I am on the Amtrak Downeastern to Boston, and I thought it would be good to find a few tutorials that I could work through while I’m there. Here is what I found:

I found this “How to build a Robot” tutorial for Solidworks. It looks to take someone from not knowing anything to doing something fairly practical: www.solidworks.com/sw/education/9959_ENU_HTML.htm

I also found a number of other tutorials and sites to check out:

Lynda.com has some SolidWorks courses: http://www.lynda.com/Solidworks-training-tutorials/1157-0.html I have taken some of their online courses before, and they were all of very high quality.. It is a paid service, but really reasonable. (http://www.lynda.com/SolidWorks-tutorials/SolidWorks-2014-Essential-Training/143606-2.html)

Professional SolidWorks training: http://solidwize.com/

www.solidprofessor.com/training-plans/solidworks/

Successfully printing bigger pieces

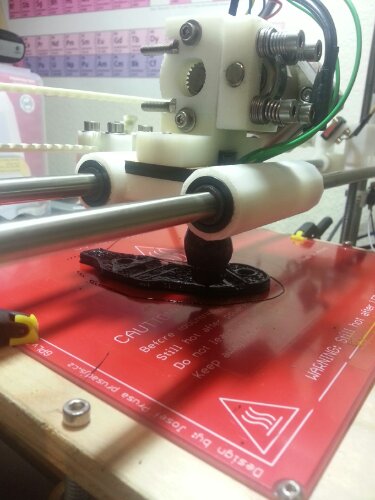

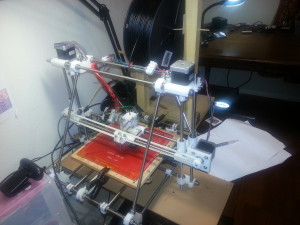

3D Printer finally together and extruding

On August 18, 2011, I ordered a Prusa Mendel 3D printer kit from MakerGear. I had seen a 3D printer at TX/RX Labs, the Hackerspace/Makerspace in Houston, TX. It was an amazing machine. I had seen videos, but there is something about seeing one in person, holding items produced by them, and talking to people that actually have used them to produce things.

The day I got the kit, I went through the physical build. Everything except for the platform. It was at that point the words “STRONGLY RECOMMEND: Mark & drill the Y-carriage mounting holes on the wood base BEFORE building the Y-carriage” from the Maker Gear instructions really made sense. Then I realized I would have to take apart a good part of it to put the table on. Also, I was having some challenges learning how to put together the extruder and hot end. Not to mention all the wiring, power supply and electronics.

After working on it for a few more days, I ended up letting it sit for a while. Then every few months I would pick it back up. December of 2012 I remember telling my family that it would be finished before Christmas, then before my birthday (just after Christmas), then by New Years (just after my birthday). But there were some challenges that I could not work through.

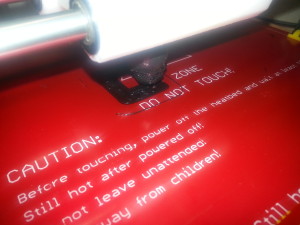

It works by melting a bit of PLA plastic and building up layer upon layer to get the shape that you want.

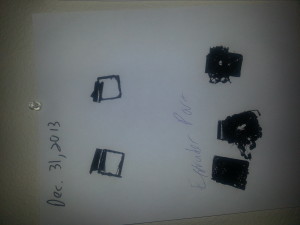

Here you can see some of the items that we have made. All very crude and imprecise.

As you can see these are more errors than success. And in the process of finding answers to the problems, I ran across many other people that have found the skills needed to do the 3D printing are a lot more difficult to develop than one thinks.

“Just because you have a 3D printer doesn’t mean you’re going to make anything remarkable. It doesn’t even mean you’re going to wind up with what you set out to produce. Believe it or not, 3D printing requires some skill. And when you don’t have it, things go delightfully askew.” Leslie Horn on Gizmodo (gizmodo.com/11-spectacular-3d-printer-failures-511092085)

Flickr group for 3d printing failures: www.flickr.com/groups/3d-print-failures/

“If you buy all the 3D printing marketing campaigns, it’s easy to start believing that 3D printing at home is not difficult at all. All you have to do is make your 3D model on your computer, dump some powder into your 3D printer, and press a button, right? Wrong. 3D printing is not easy and leaves plenty of room for mistakes and errors to be made by rookies.” –Inkpal.com www.inkpal.com/ink-news/3d-printing-at-home-not-easy-mistakes-errors-failures/

How to fix 3D printer issues: www.bilbycnc.com.au/3DPrintingProblems.asp

The good thing is that I have a very good understanding of how the 3D printer works. I think once I work through my issues I can print out the plastic components, but the hardware, electronics, and motors, and try making a new one from scratch.

Happy New Year!

“HAPPY NEW YEAR” was the text message I received. “Thanks!! Happy new year!! Any new year’s resolutions?” I texted back.

Setting New Years resolutions is a traditional as fireworks (and often just as short lived.) Setting them is something that we do every year, and often forget by the mid part of January. We usually think of them at the last moment on Dec. 31st, or when we are asked. Or it is something that we have been struggling to do for a while and are looking for a way to make progress.

“Be happier — how about you?” is what I got back.

Seems like a good goal. But how does one “become happier”? My experience is that trying to be happy is sort of like trying to fall asleep. The more you focus on it, the less likely it is to happen. “Happiness is something that happens when you are making other plans” is what my Grandmother used to say. So, what are the other plans that I plan to make?

“I was thinking of blogging something on gadgetnate.com everday. I fiture if I have to write something everyday then it would force me to do something worth writing about.”

Or at least force me to look at part of my life, think about it, and put it in a form that would make sense on paper. So that is my new year’s resolution. And I hear by designate all you you readers out there my accountability partners to make sure I stay on track.